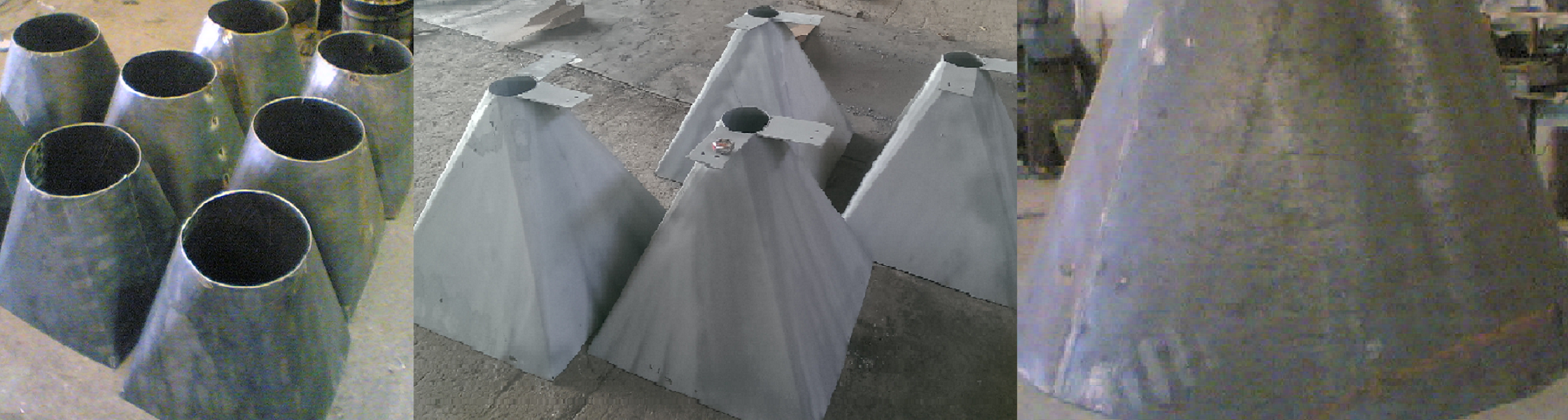

Fabrication of Cones and Reducers

JCMARVEL Engineering and Trading LLP executes the fabrication and supply of Cones and Reducers for various industrial applications.

Our Fabrication Processes

1. Detailing

Based on your design, we pepare the shop fabrication drawings and layouts for cones & reducers.

2. Procurement

Sourcing materials from reliable supply sources, matching Mill Test Certificates and tracking.

3. Fabrication

Various shop fabrication processes like layout generation, cutting, grinding, bends, edge preparation etc.

4. Assembly

Fabricated parts are fitup and assembled for welding in a phased manner for welding commencement.

5. Welding

Strict conformity to WPS / PQR. Use of reliable experienced welders to produce sound weld joints.

6. Testing & NDT

As per project ITP, stagewise inspection, DP, MPT, UT, RT, Dimensional Inspection Tests etc. are performed.

7. Coatings

Blasting & Painting of Steel Cones & Reducers as per NACE / SSPC. Passivation and/or Pickling for SS items.

8. Delivery

Loading & shipment to client on third party transport, or loading in client arranged transport vehicles.

Shapes & Parameters

Concentric/Eccentric: Cones and Reducers can be made as Concentric Cones and Concentric Reducers. Else they can be made as Eccentric Cones and Eccentric Reducers

Trasition Types: Cones and Reducers can be shaped as circular to circular, circular to square, circular to rectangle, circular to polygonal, or polygonal to polygonal, depending on your needs.

Reducing Elbows: We can even manufacture miter type reducing elbows depending on your dimensional requirements as 3D, 5D etc.

Typical Specifications

Materials: A variety of carbon steels and stainless steels grades can be used in fabrication. Usual grades are mild steel, A36, SA516, SS304, SS304L, SS316, and SS 316L.

Applications: Cones and Reducers are used where a difference in cross section is encountered in ducting, piping, tanks etc. In practical applications, the axis at both ends may be offset to be eccentric.

Media / Fluid Types: Cones and reducers handle various media and fluids like granular solids, lumpy materials, crude, fuel, oil, chemicals, water etc.